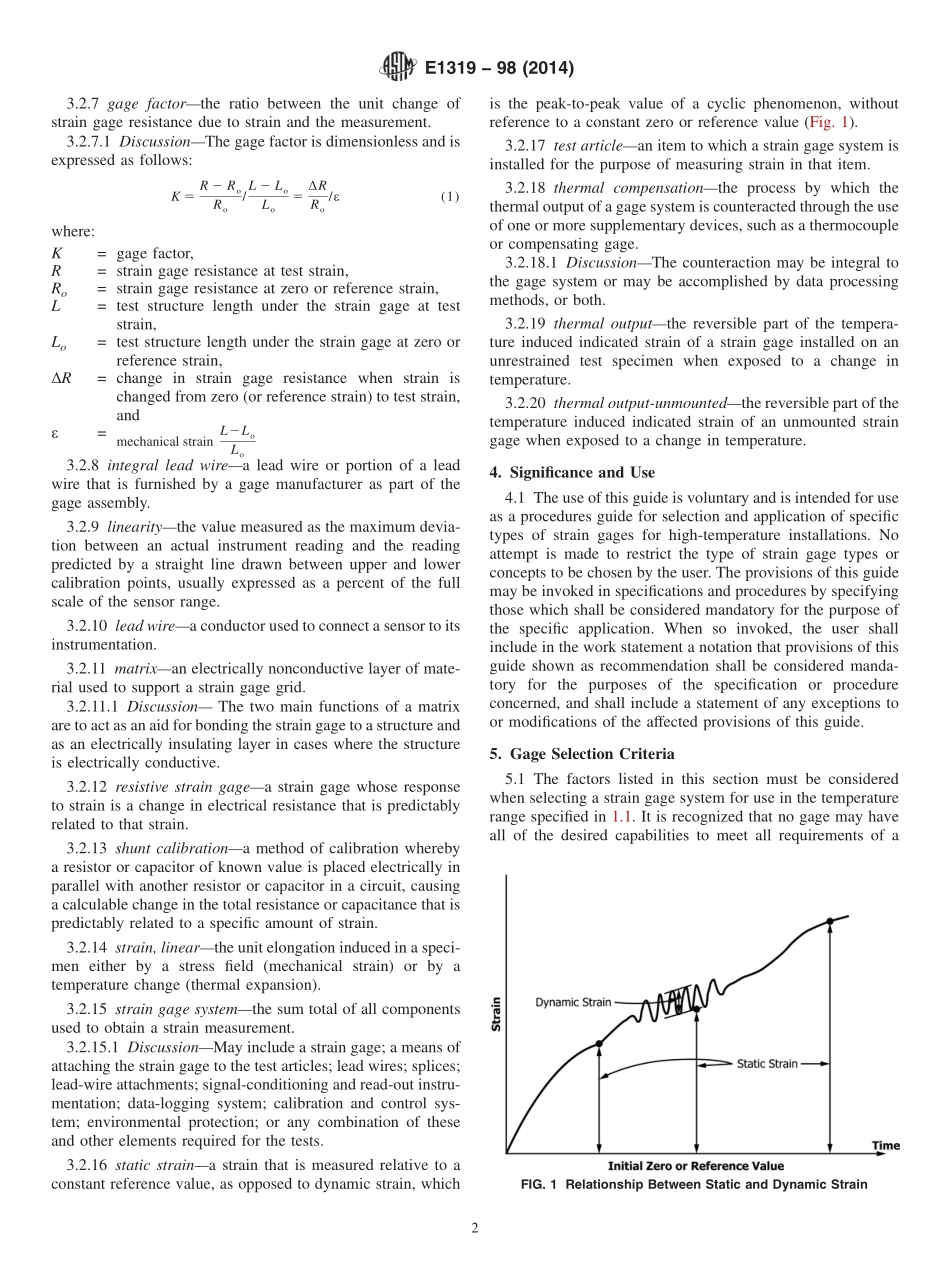

Designation:E1319−98(Reapproved2014)StandardGuideforHigh-TemperatureStaticStrainMeasurement1ThisstandardisissuedunderthefixeddesignationE1319;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisguidecoverstheselectionandapplicationofstraingagesforthemeasurementofstaticstrainuptoandincludingthetemperaturerangefrom425to650°C(800to1200°F).Thisguidereflectssomecurrentstate-of-the-arttechniquesinhightemperaturestrainmeasurement,andwillbeexpandedandupdatedasnewtechnologydevelops.1.2Thisguideassumesthattheuserisfamiliarwiththeuseofbondedstraingagesandassociatedsignalconditioningandinstrumentationasdiscussedin(1)and(2).2Thestrainmeasuringsystemsdescribedarethosethathaveproveneffectiveinthetemperaturerangeofinterestandwereavailableatthetimeofissueofthisguide.Itisnottheintentofthisguidetolimittheusertooneofthegagetypesdescribednorisittheintenttospecifythetypeofsystemtobeusedforaspecificapplication.However,inusinganystrainmeasuringsystemincludingthosedescribed,theproposermustbeabletodemonstratethecapabilityoftheproposedsystemtomeettheselectioncriteriaprovidedinSection5andtheneedsofthespecificapplication.1.3Thedevicesandtechniquesdescribedinthisguidemaybeapplicableattemperaturesaboveandbelowtherangenoted,andformakingdynamicstrainmeasurementsathightempera-tureswithproperprecautions.Thegagemanufacturershouldbeconsultedforrecommendationsanddetailsofsuchappli-cations.1.4Thereferencesareapartofthisguidetotheextentspecifiedinthetext.1.5Thevaluesstatedinmetric(SI)unitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationalpurposesonly.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofreg...