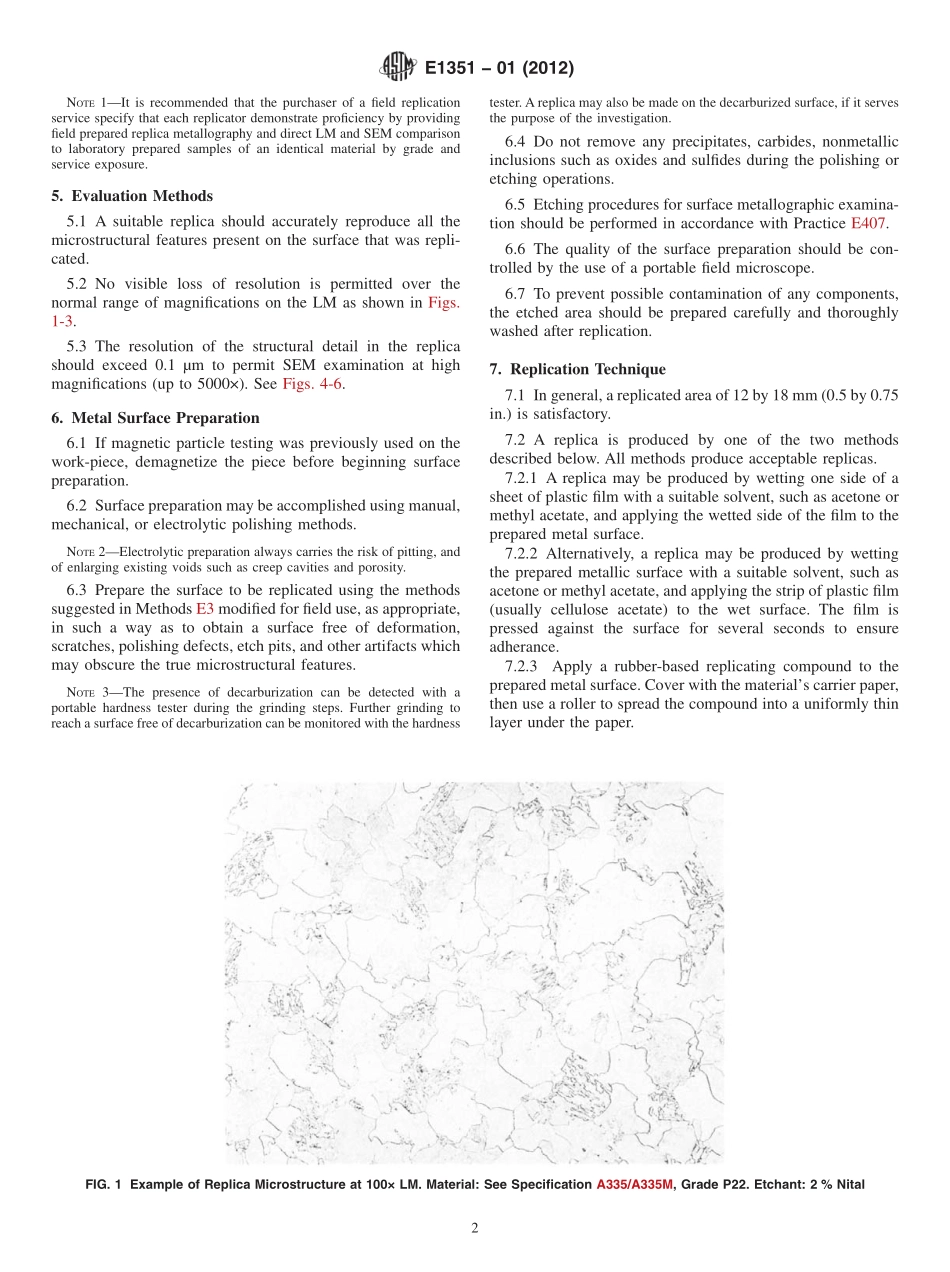

Designation:E1351−01(Reapproved2012)StandardPracticeforProductionandEvaluationofFieldMetallographicReplicas1ThisstandardisissuedunderthefixeddesignationE1351;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INTRODUCTIONReplicationisanondestructivesamplingprocedurewhichrecordsandpreservesthetopographyofametallographicspecimenasanegativereliefonaplasticfilm.Themicrostructuralreplicacanbeexaminedusingalightmicroscope(LM)orscanningelectronmicroscope(SEM)forsubsequentanalysis.SpecimensexaminedintheSEMarevacuumcoatedwithvaporizedcarbonorasuitablemetaltoprovidecontrastandconductivity.Theconvenienceofthereplicationprocessmakesitsuitableforobtainingmicrostructuresfromfieldlocationsforsubsequentexaminationandanalysisinalaboratory.Theproperpreparationofthetestsurfaceandofthereplicaitselfisofparamountimportanceandmustreceivecarefulattention.Becauseofthediversityofmetallographicequipmentavailableandthewiderangeofenvironmentsinwhichreplicationisconducted,thepreparationofreplicasofhighqualityshouldbeviewedasaskilledprocessforwhichthereexistsavarietyoftechniquesthatachievesatisfactoryresults.Thispracticepresentssomeguidelinesonthepreparationofmetallicsurfacesandproductionofreplicasandguidelinesonevaluationofreplicaquality.Itdoesnotattempttolimitthevariationsintechniquedevelopedbyskilledmetallographers,eachofwhichmayproduceacceptablereplicas.1.Scope1.1Thispracticecoversrecognizedmethodsfortheprepa-rationandevaluationofcelluloseacetateorplasticfilmreplicaswhichhavebeenobtainedfrommetallographicallypreparedsurfaces.ItisdesignedfortheevaluationofreplicastoensurethatallsignificantfeaturesofametallographicallypreparedsurfacehavebeenduplicatedandpreservedonthereplicawithsufficientdetailtopermitbothLMandSEMexaminationwithoptimumresolutionandsensitivity.1.2Thispracticemaybeusedasaco...