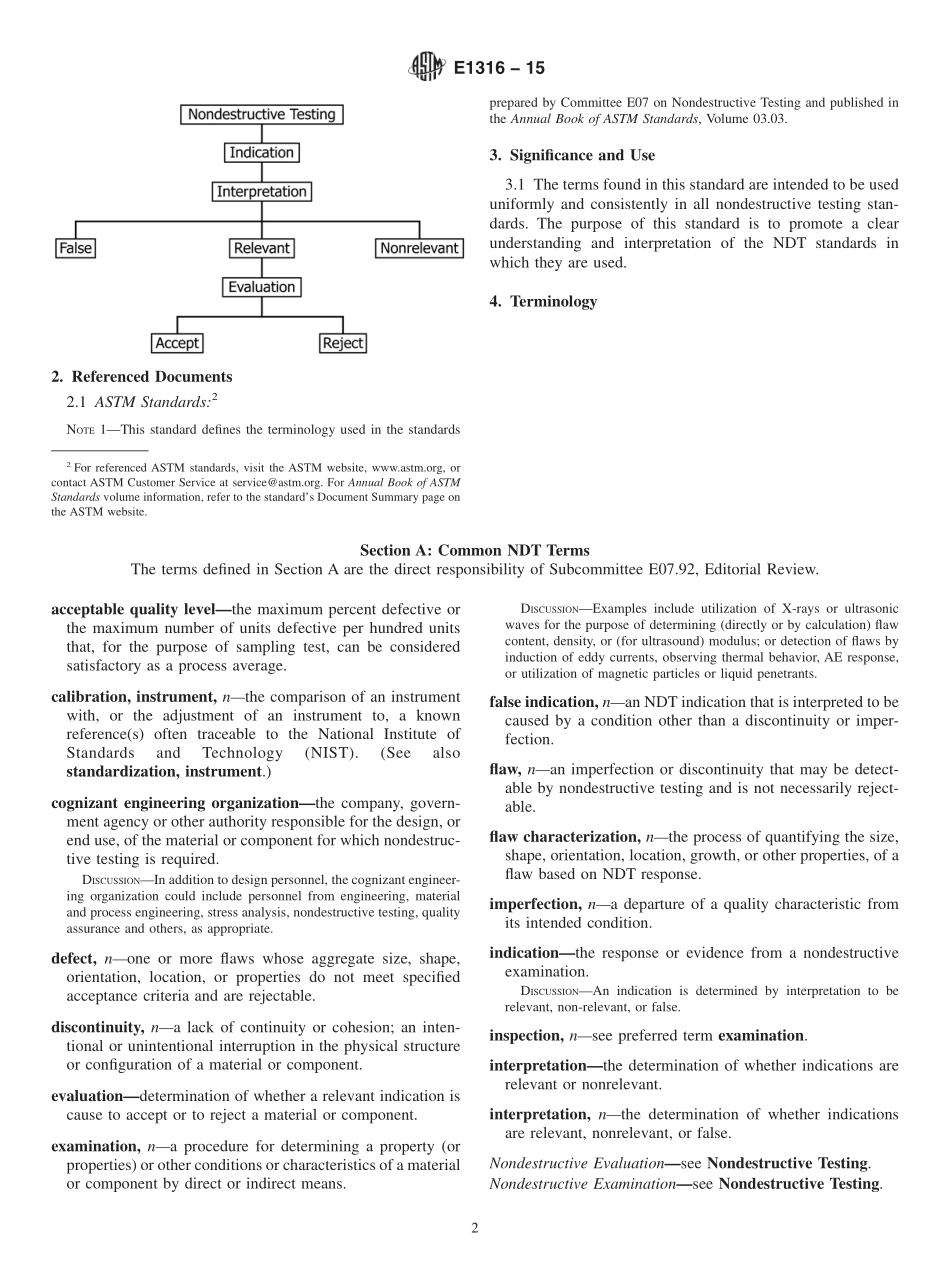

Designation:E1316−15StandardTerminologyforNondestructiveExaminations1ThisstandardisissuedunderthefixeddesignationE1316;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INDEXOFTERMSSectionA:CommonNDTTermsB:AcousticEmission(AE)TermsC:ElectromagneticTesting(ET)TermsD:Gamma-andX-RadiologicTesting(RT)TermsE:LeakTesting(LT)TermsF:LiquidPenetrantTesting(PT)TermsG:MagneticParticleTesting(MT)TermsH:NeutronRadiologicTesting(NRT)TermsI:UltrasonicTesting(UT)TermsJ:InfraredTesting(IRT)TermsK:HolographicTesting(HT)TermsL:VisualTesting(VT)Terms1.Scope1.1ThisstandarddefinestheterminologyusedinthestandardspreparedbytheE07CommitteeonNondestructiveTesting.Thesenondestructivetesting(NDT)methodsinclude:acousticemission,electromagnetictesting,gamma-andX-radiology,leaktesting,liquidpenetranttesting,magneticparticletesting,neutronradiologyandgauging,ultrasonictesting,andothertechnicalmethods.1.2CommitteeE07recognizesthatthetermsexamination,testingandinspectionarecommonlyusedassynonymsinnondestructivetesting.ForuniformityandconsistencyinE07nondestructivetestingstandards,CommitteeE07encouragestheuseofthetermexaminationanditsderivativeswhendescribingtheapplicationofnondestructivetestmethods.Thereare,however,appropriateexceptionswhenthetermtestanditsderivativesmaybeusedtodescribetheapplicationofanondestructivetest,suchasmeasurementswhichproduceanumericresult(forexample,whenusingtheleaktestingmethodtoperformaleaktestonacomponent,oranultrasonicmeasurementofvelocity).Additionally,thetermtestshouldbeusedwhenreferringtotheNDTmethod,thatis,RadiologicTesting(RT),UltrasonicTesting(UT),andsoforth.(Example:RadiologicTesting(RT)isoftenusedtoexaminematerialtodetectinternaldiscontinuities.)1.3SectionAdefinestermsthatarecommontomultipleNDTmethods,whereas,thesubsequentsectionsdefinetermspertainingtos...