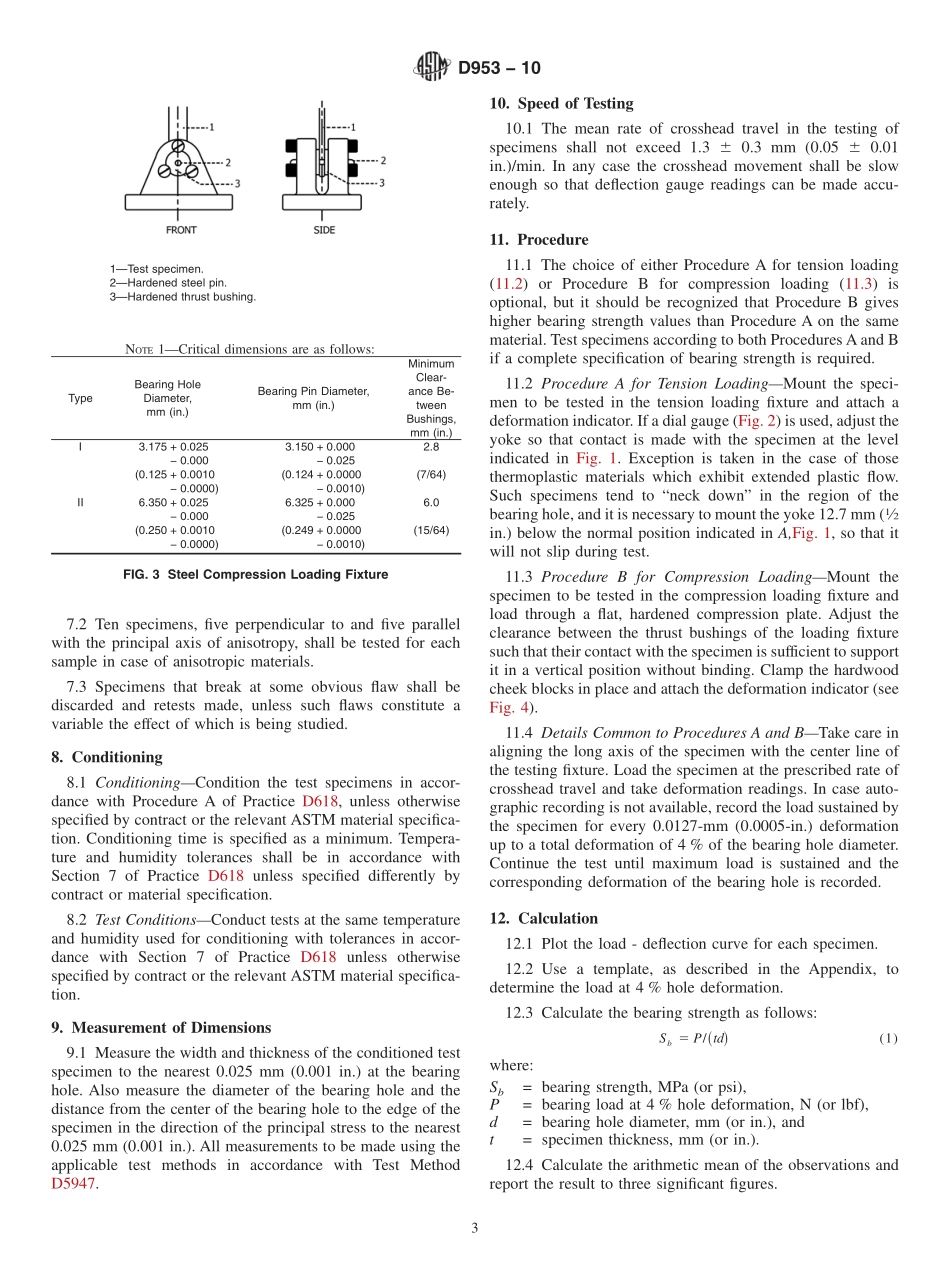

Designation:D953−10StandardTestMethodforBearingStrengthofPlastics1ThisstandardisissuedunderthefixeddesignationD953;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoversthedeterminationofthebearingstrengthofrigidplasticsineithersheetform,moldedform,orinthermosetpultrudedform.ProcedureAisapplicablefortensionloadingandProcedureBforcompressionloading.1.2Testdataobtainedbythistestmethodisrelevantandappropriateforuseinengineeringdesign.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD883TerminologyRelatingtoPlasticsD5947TestMethodsforPhysicalDimensionsofSolidPlasticsSpecimensE4PracticesforForceVerificationofTestingMachinesE6TerminologyRelatingtoMethodsofMechanicalTesting3.Terminology3.1Definitions—Fordefinitionsoftechnicaltermspertain-ingtoplasticsusedinthistestmethod,seeTerminologyD883.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1bearingarea—thediameteroftheholemultipliedbythethicknessofthespecimen.3.2.2bearingstrength—thebearingstressatwhichthebearingholeisdeformed4%ofitsdiameter.3.2.3bearingstress—theappliedloadinnewtons(orpounds-force)dividedbythebearingareainmm2(orin2).3.2.4edgedistanceratio—thedistancefromthecenterofthebearingholetotheedgeofthespecimeninthedirectionoftheprincipalstress,dividedbythediameterofthehole.3.2.5maximumb...