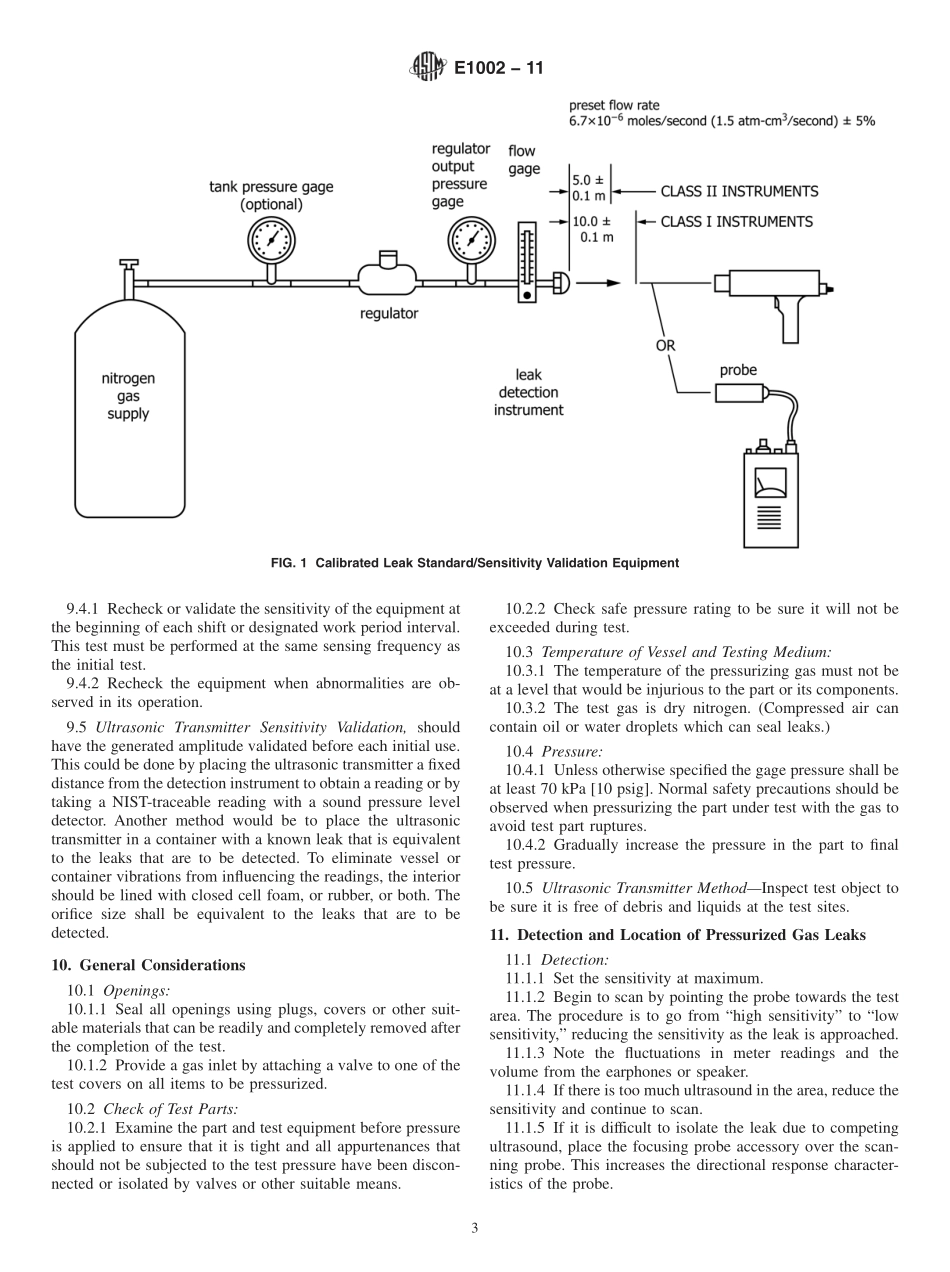

Designation:E1002−11StandardPracticeforLeaksUsingUltrasonics1ThisstandardisissuedunderthefixeddesignationE1002;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1PracticeA,Pressurization—Thispracticecoversproce-duresforcalibrationofultrasonicinstruments,location,andestimatedmeasurementsofgasleakagetoatmospherebytheairborneultrasonictechnique.21.2Ingeneralpracticethisshouldbelimitedtoleaksdetectedbytwoclassificationsofinstruments,ClassIandClassII.ClassIinstrumentsshouldhaveaminimumdetectableleakrateof6.7×10−7mol/s(1.5×10−2std.cm3/sat0°C)ormoreforthepressuremethodofgasleakagetoatmosphere.ClassIIinstrumentsshouldhaveaminimaldetectableleakrateof6.7×10−6mol/s(1.5×10−1std.cm3/sat0°C)ormoreforthepressuremethodofgasleakagetoatmosphere.RefertoGuideE432foradditionalinformation.1.3PracticeB,UltrasonicTransmitter—Forobjectundertestnotcapableofbeingpressurizedbutcapableofhavingultrasonictoneplaced/injectedintothetestareatoactasanultrasonicleaktracesource.1.3.1Thispracticeislimitedtoleaksproducingleakageof6.7×10−6mol/s(1.5×10−1std.cm3/sat0°C)orgreater.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoconsultandestablishappropriatesafetyandhealthpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3E432GuideforSelectionofaLeakTestingMethodE543SpecificationforAgenciesPerformingNondestructiveTestingE1316TerminologyforNondestructiveExaminations2.2OtherDocuments:SNT-TC-1ARecommendedPracticeforPersonnelQualifi-cationandCertificationinNondestructiveTesting4ANSI/ASNTCP-189ASNTStandardforQualificationandCertificationofNondestructiveTestingPersonnel4NAS-410Certifi...