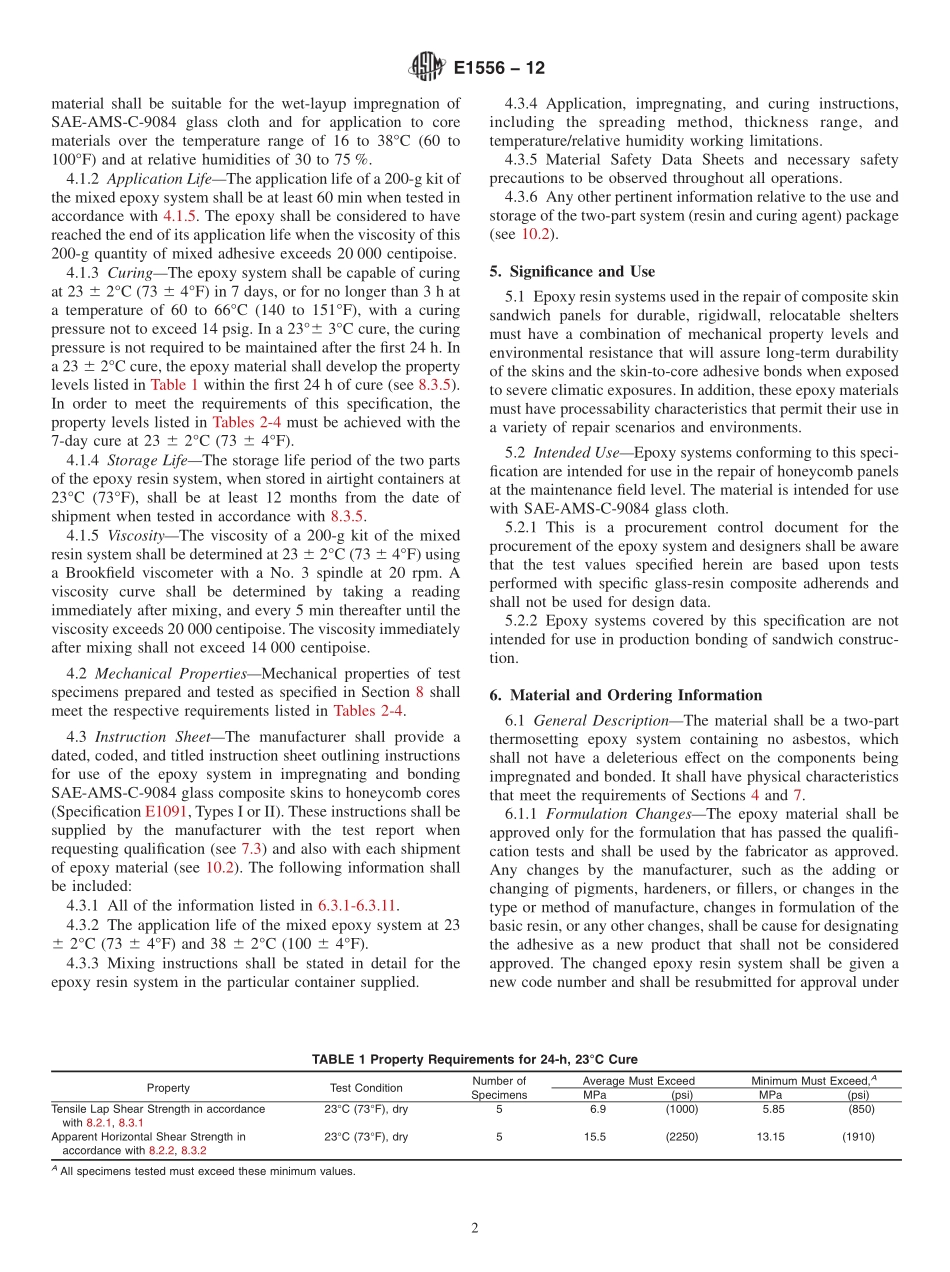

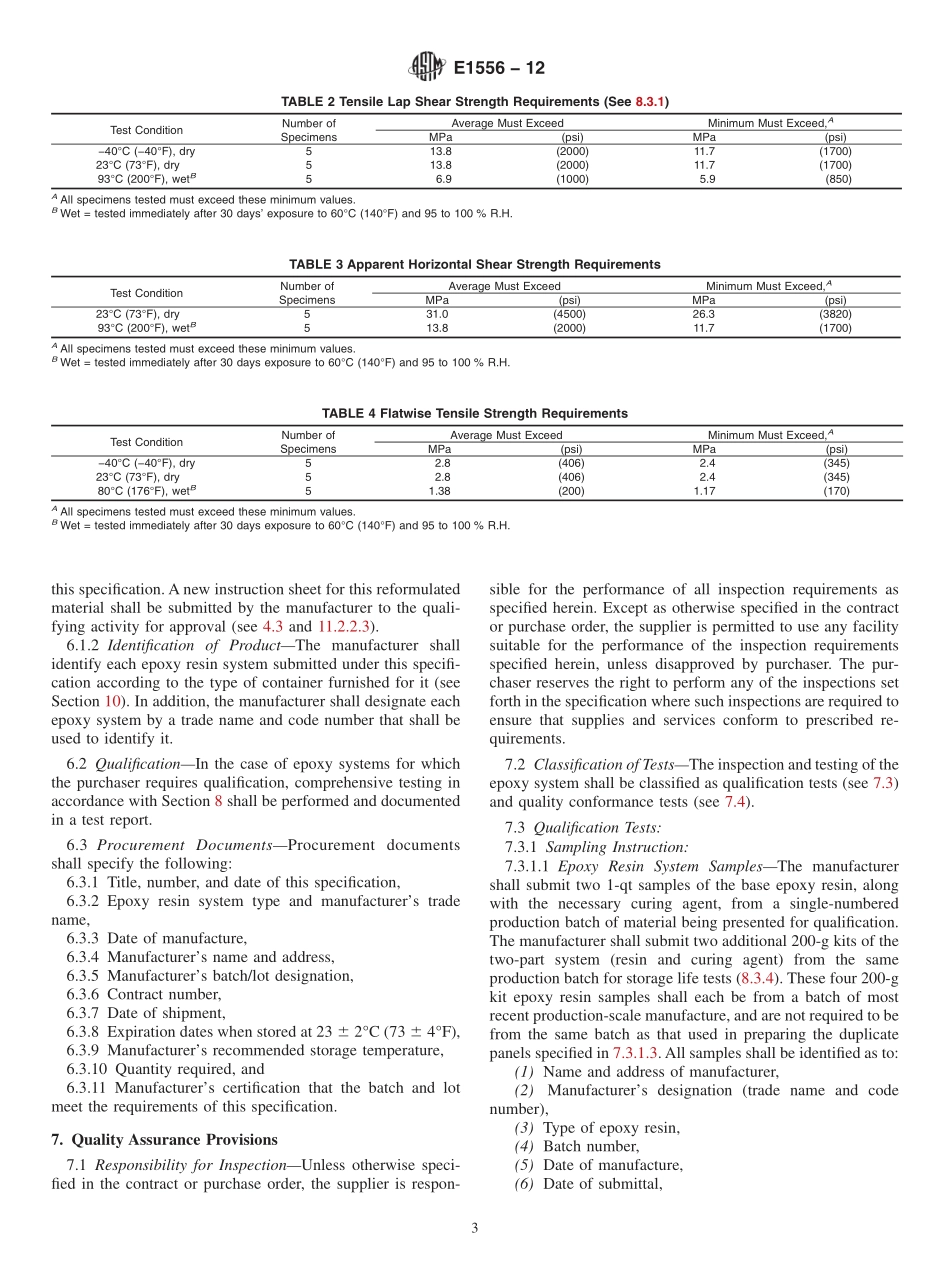

Designation:E1556−12StandardSpecificationforEpoxyResinSystemforCompositeSkin,HoneycombSandwichPanelRepair1ThisstandardisissuedunderthefixeddesignationE1556;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoverstherequirementsforanepoxyresinsystemintendedfortherepairofsandwichpanelsfordurable,rigidwall,relocatablestructures.Itmustbeusableinafieldenvironmentandshallnotrequiretheuseofspecialequipmentsuchasautoclavesorpresses.Theepoxysystemcoveredbythisspecificationshallbeusableforsimultaneousimpregnationofawet-layupcompositeskinandbondingofthatskintoasubstratehoneycombcore.Thematerialshallwithstandexposuretotemperaturesfrom−54to93°C(−65to199°F)andhighrelativehumidity,andalsothecombinationofstress,temperature,andrelativehumiditythatareexpectedtobeencounteredinservice.1.2ThevaluesstatedinSIunitsaretoberegardedasstandardwhereonlySIunitsaregivenorwhereSIunitsaregivenfirstfollowedbyinch-poundunits;whereinch-poundunitsaregivenfirstfollowedbySIunits,theinch-poundunitsaretoberegardedasthestandard.1.3Thefollowingsafetyhazardscaveatrefersonlytothetestmethodsdescribedinthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C297/C297MTestMethodforFlatwiseTensileStrengthofSandwichConstructionsD792TestMethodsforDensityandSpecificGravity(Rela-tiveDensity)ofPlasticsbyDisplacementD2344/D2344MTestMethodforShort-BeamStrengthofPolymerMatrixCompositeMaterialsandTheirLaminatesD2584TestMethodforIgnitionLossofCuredReinforcedResinsD2734TestMethodsforVoi...