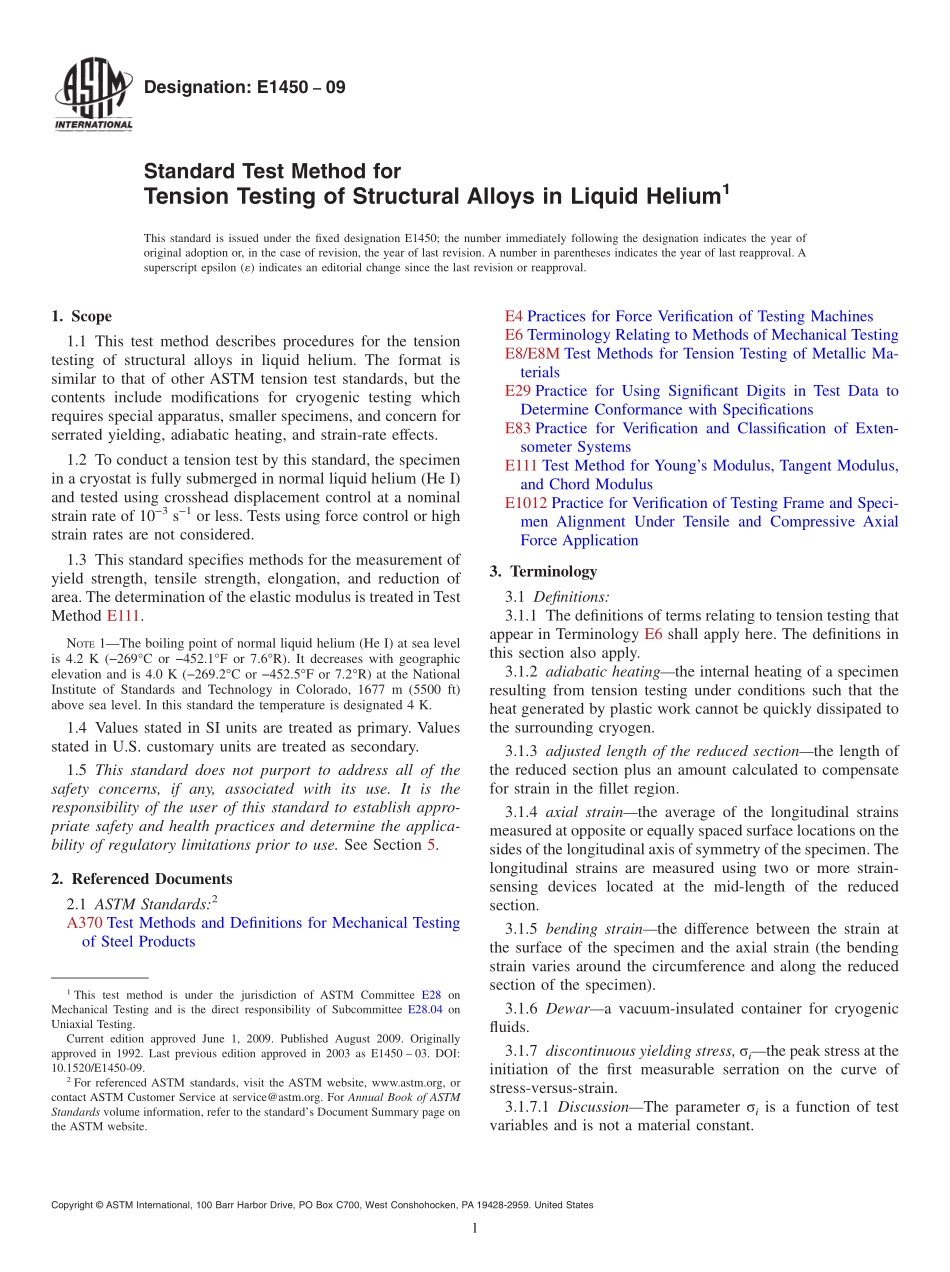

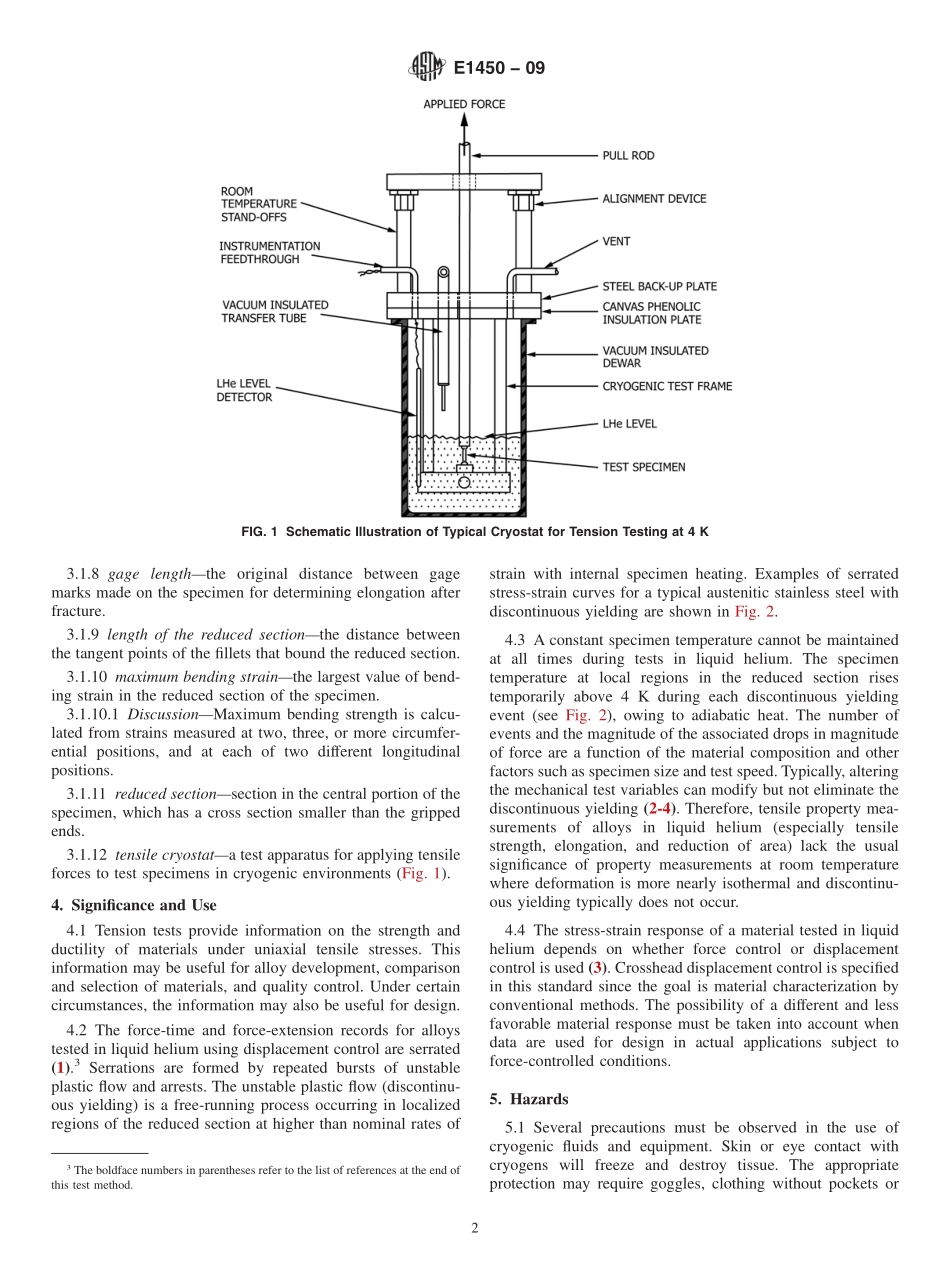

Designation:E1450−09StandardTestMethodforTensionTestingofStructuralAlloysinLiquidHelium1ThisstandardisissuedunderthefixeddesignationE1450;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribesproceduresforthetensiontestingofstructuralalloysinliquidhelium.TheformatissimilartothatofotherASTMtensionteststandards,butthecontentsincludemodificationsforcryogenictestingwhichrequiresspecialapparatus,smallerspecimens,andconcernforserratedyielding,adiabaticheating,andstrain-rateeffects.1.2Toconductatensiontestbythisstandard,thespecimeninacryostatisfullysubmergedinnormalliquidhelium(HeI)andtestedusingcrossheaddisplacementcontrolatanominalstrainrateof10−3s−1orless.Testsusingforcecontrolorhighstrainratesarenotconsidered.1.3Thisstandardspecifiesmethodsforthemeasurementofyieldstrength,tensilestrength,elongation,andreductionofarea.ThedeterminationoftheelasticmodulusistreatedinTestMethodE111.NOTE1—Theboilingpointofnormalliquidhelium(HeI)atsealevelis4.2K(−269°Cor−452.1°For7.6°R).Itdecreaseswithgeographicelevationandis4.0K(−269.2°Cor−452.5°For7.2°R)attheNationalInstituteofStandardsandTechnologyinColorado,1677m(5500ft)abovesealevel.Inthisstandardthetemperatureisdesignated4K.1.4ValuesstatedinSIunitsaretreatedasprimary.ValuesstatedinU.S.customaryunitsaretreatedassecondary.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.SeeSection5.2.ReferencedDocuments2.1ASTMStandards:2A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsE4PracticesforForceVerificationofTestingMachinesE6TerminologyRelatingtoMethodsofMechanicalTestingE8/E8MTestMethodsforTen...