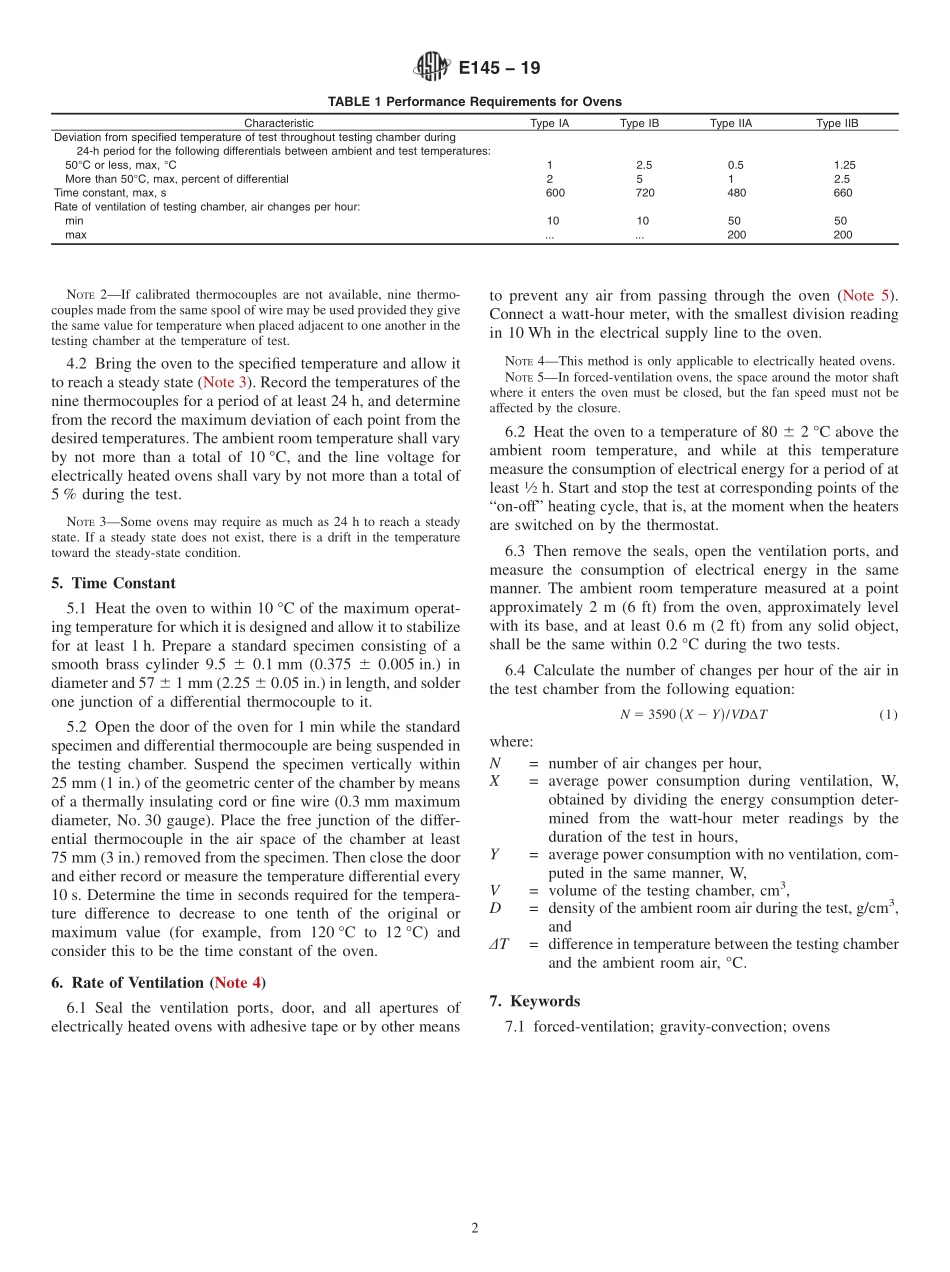

Designation:E145−19StandardSpecificationforGravity-ConvectionandForced-VentilationOvens1ThisstandardisissuedunderthefixeddesignationE145;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcoverstheperformancerequirementsforgeneral-purposeairovensordinarilyusedintestingoperations,whichhaveatestingchamberupto0.6m3(25ft3)involume.Itisapplicabletogravity-convectionovensde-signedtooperateoverallorpartofthetemperaturerangefrom20°Caboveambienttemperatureto200°Candtoforced-ventilationovensdesignedtooperateoverallorpartofthetemperaturerangefrom20°Caboveambienttemperatureto500°C.NOTE1—Ovensaredesignedformaximumoperatingtemperaturesofabout200°C,300°C,and500°C,thethermalinsulationandcostoftheovenbeingdependentonthemaximumtemperaturerequired.1.2Thisspecificationdoesnotincludesafetyrequirementsthatareessentialforovensusedinthepresenceofcombustiblevaporsorgases.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesafterSIunitsareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.Types2.1Thisspecificationcoversthefollowingfourtypesofairovens:2.1.1TypeIA—anovenventilatedbygravityconvectionhavingauniformityoft...