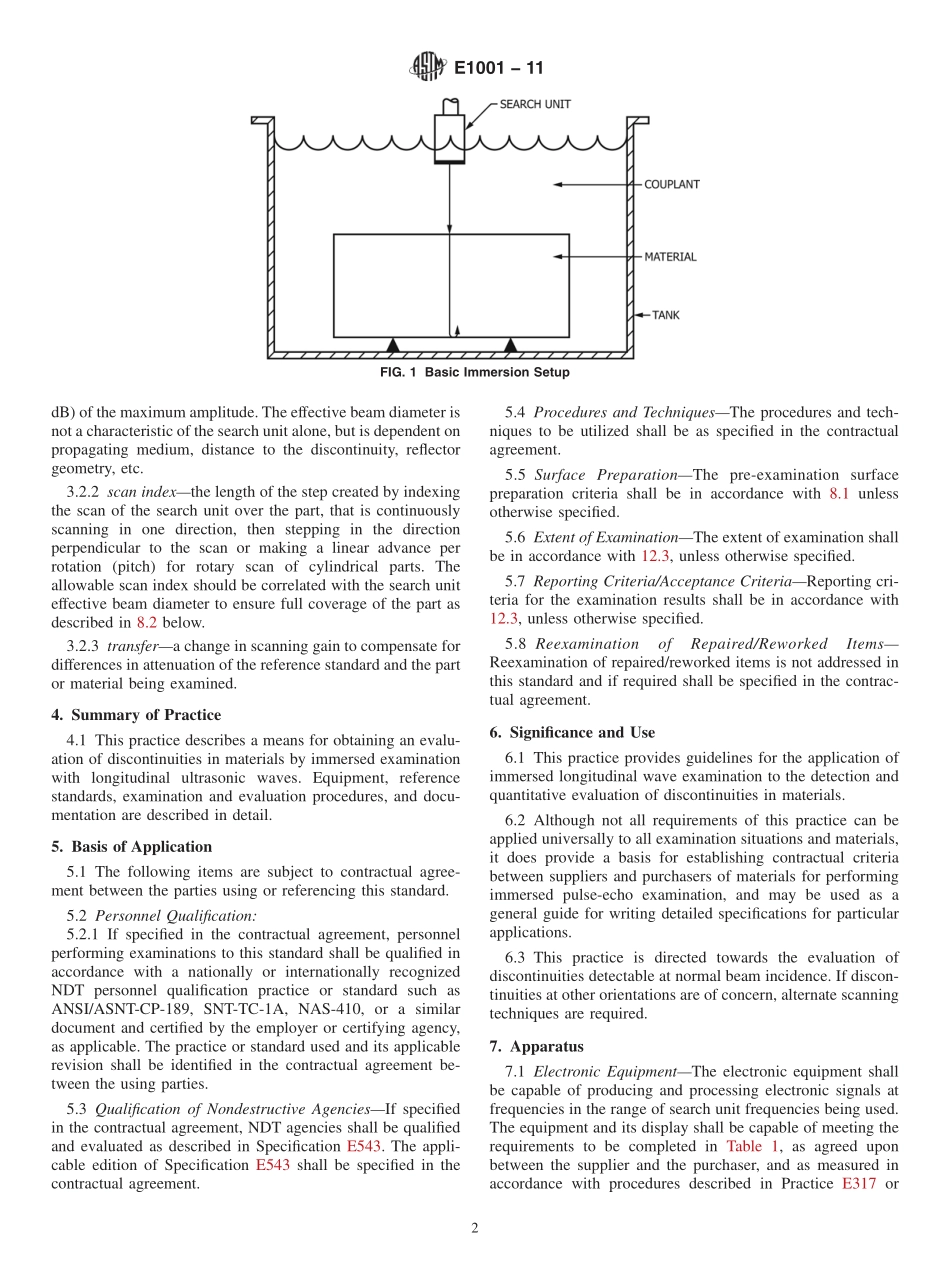

Designation:E1001−11StandardPracticeforDetectionandEvaluationofDiscontinuitiesbytheImmersedPulse-EchoUltrasonicMethodUsingLongitudinalWaves1ThisstandardisissuedunderthefixeddesignationE1001;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thispracticedescribesproceduresfortheultrasonicexaminationofbulkmaterialsorpartsbytransmittingpulsed,longitudinalwavesthroughaliquidcouplantintothematerialandobservingtheindicationsofreflectedwaves(seeFig.1).Itcoversonlyexaminationsinwhichonesearchunitisusedasbothtransmitterandreceiver(pulse-echo)andinwhichthepartormaterialbeingexaminediscoupledtothepartbyaliquidcolumnoristotallysubmergedinthecouplant(eithermethodisconsideredtobeimmersiontesting).Thispracticeincludesgeneralrequirementsandprocedureswhichmaybeusedfordetectingdiscontinuitiesandformakingarelativeorapproxi-mateevaluationofthesizeofdiscontinuities.1.2ThispracticereplacesPracticeE214andprovidesmoredetailedproceduresfortheselection,standardization,andoperationofanexaminationsystemandforevaluationoftheindicationsobtained.1.3Units—Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C1212PracticeforFabricatingCeramicReferenceSpeci-mensContainingSeededVoidsC1336PracticeforFabricatingNon-OxideCeramicRefer-enceSpecimensContainingSeededInclusionsE127PracticeforFabricatingandCheckingAlumi...