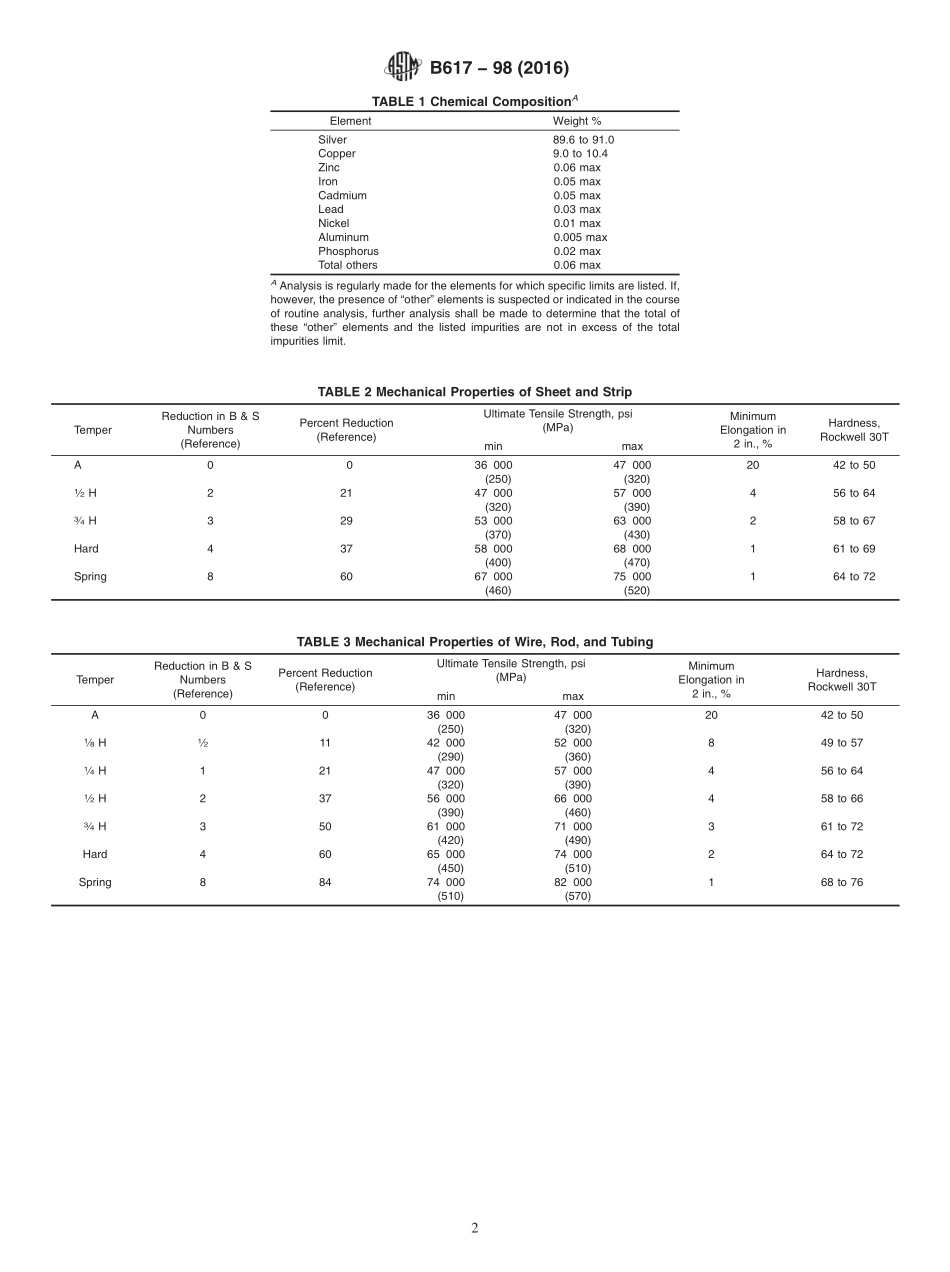

Designation:B617−98(Reapproved2016)StandardSpecificationforCoinSilverElectricalContactAlloy1ThisstandardisissuedunderthefixeddesignationB617;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcovers90%silver-10%copperalloytubing,rod,wire,strip,andsheetmaterialforelectricalcontacts.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtobecomefamiliarwithallhazardsincludingthoseidentifiedintheappropriateSafetyDataSheet(SDS)forthisproduct/materialasprovidedbythemanufacturer,toestablishappropriatesafetyandhealthpractices,anddeterminetheapplicabilityofregulatorylimi-tationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B277TestMethodforHardnessofElectricalContactMate-rialsB476SpecificationforGeneralRequirementsforWroughtPreciousMetalElectricalContactMaterials3.Manufacture3.1Rawmaterialsshallbeofsuchqualityandpuritythatthefinishedproductwillhavethepropertiesandcharacteristicsprescribedinthisspecification.3.2Thematerialshallbefinishedbysuchoperations(coldworking,heattreating,annealing,turning,grinding,orpick-ling)asarerequiredtoproducetheprescribedproperties.4.ChemicalComposition4.1MaterialproducedunderthisspecificationshallmeettherequirementsforchemicalcompositionprescribedinTable1.5.MechanicalRequirements5.1MechanicalpropertiesshallconformtothelistingsofTable2orTable3.5.2Alltestspecimensshallbefullthicknessordiameterwhenpractical.5.3Alltestsaretobeconductedatroomtemperature,about68°F(20°C).6.GeneralRequir...