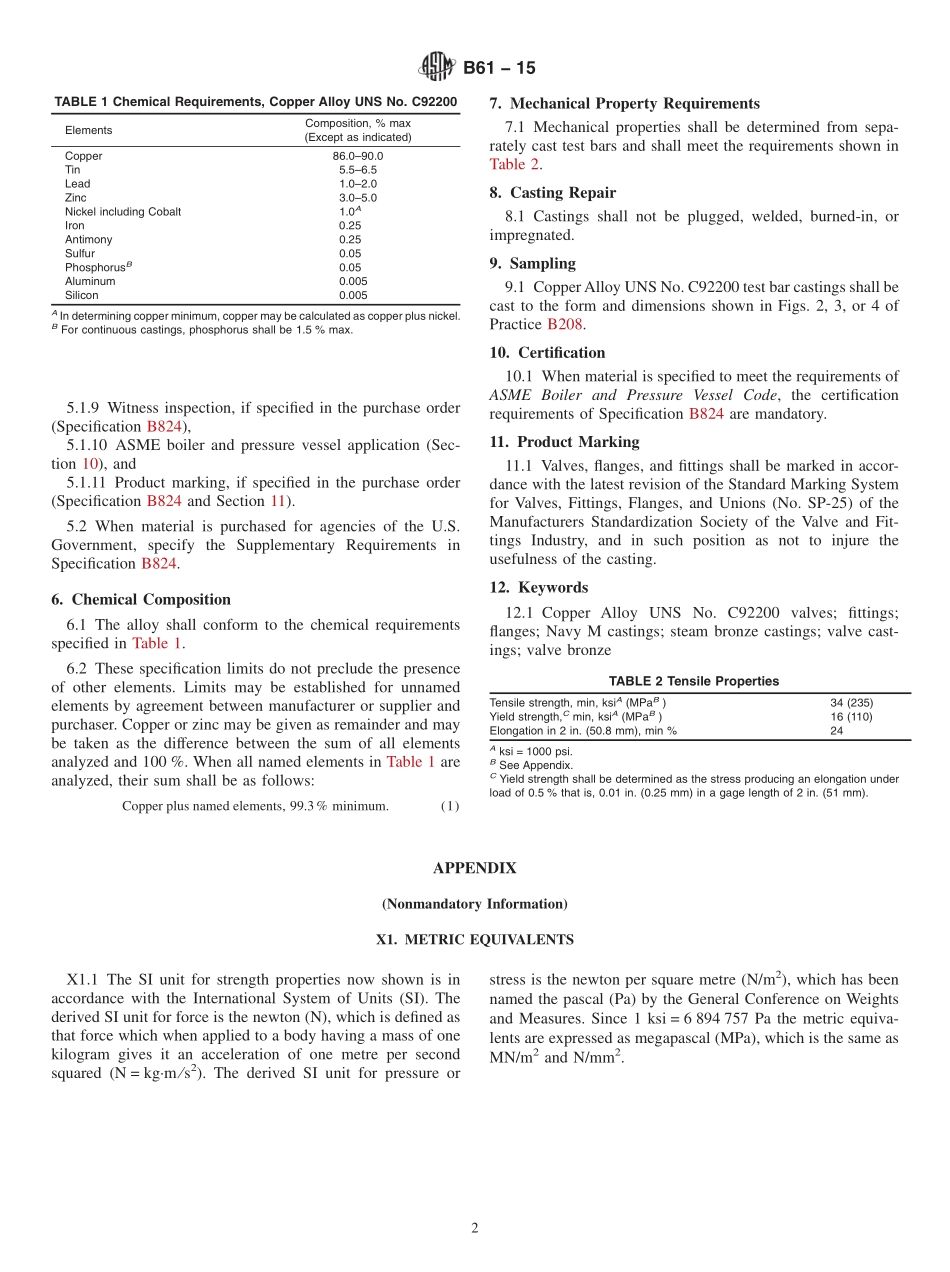

Designation:B61−15StandardSpecificationforSteamorValveBronzeCastings1ThisstandardisissuedunderthefixeddesignationB61;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecification2establishesrequirementsforahigh-gradesteam-metalorvalve-bronzealloy(CopperAlloyUNSNo.C922003)usedforcomponentcastingsofvalves,flanges,andfittings.1.2Thecastingscoveredareusedinproductsthatmaybemanufacturedinadvanceandsuppliedfromstockbythemanufacturerorotherdealer.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:4B208PracticeforPreparingTensionTestSpecimensforCopperAlloySand,PermanentMold,Centrifugal,andContinuousCastingsB824SpecificationforGeneralRequirementsforCopperAlloyCastingsB846TerminologyforCopperandCopperAlloysE527PracticeforNumberingMetalsandAlloysintheUnifiedNumberingSystem(UNS)2.2MSSStandards:5SP-25StandardMarkingSystemforValves,Fittings,FlangesandUnions3.GeneralRequirements3.1ThefollowingsectionsofSpecificationB824formapartofthisspecification.IntheeventofaconflictbetweenthisspecificationandSpecificationB824,therequirementsofthisspecificationshalltakeprecedence.3.1.1Terminology(Section3),3.1.2OtherRequirements(Section7),3.1.3Dimensions,Mass,andPermissibleVariations(Sec-tion8),3.1.4Workmanship,Finish,andAppearance(Section9),3.1.5Sampling(Section10),3.1.6NumberofTestsandRetests(Section11),3.1.7SpecimenPreparation(Section12),3.1.8TestMethods(Section13),3.1.9SignificanceofNumericalLimits(Section14),3.1.10Inspection(Section15),3.1.11RejectionandRehearing(Section16),3.1.12Certification(Section17),3.1.13TestReport(Section...