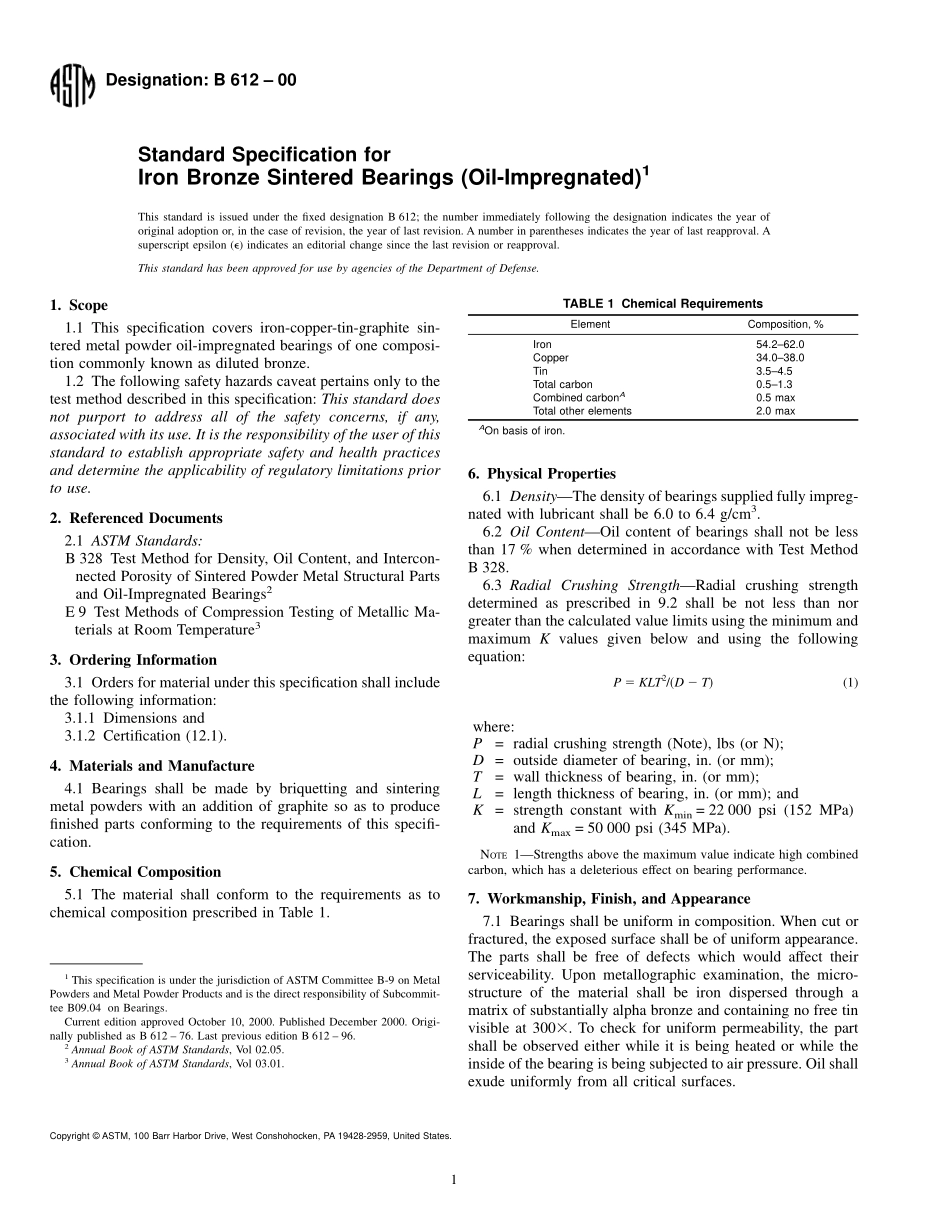

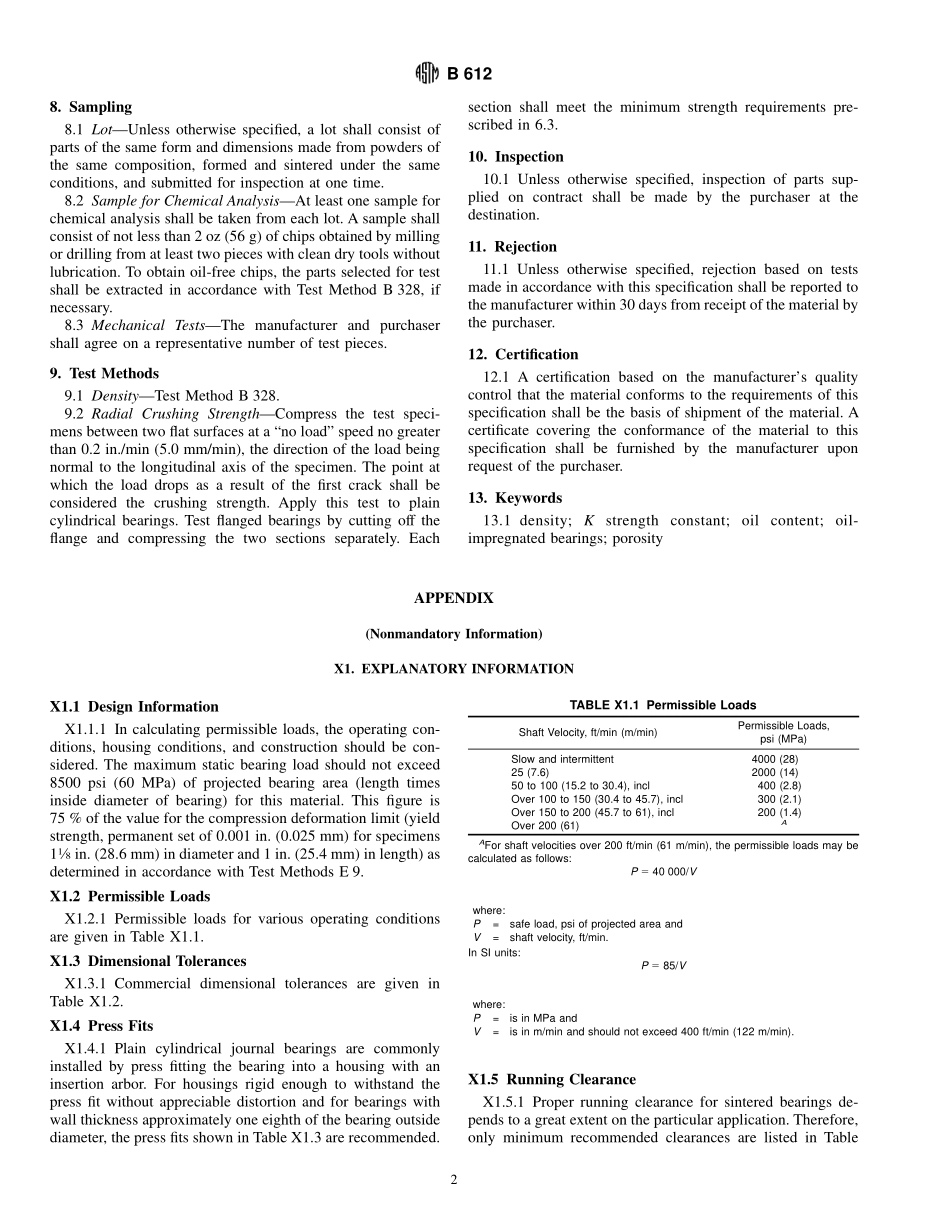

Designation:B612–00StandardSpecificationforIronBronzeSinteredBearings(Oil-Impregnated)1ThisstandardisissuedunderthefixeddesignationB612;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoversiron-copper-tin-graphitesin-teredmetalpowderoil-impregnatedbearingsofonecomposi-tioncommonlyknownasdilutedbronze.1.2Thefollowingsafetyhazardscaveatpertainsonlytothetestmethoddescribedinthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:B328TestMethodforDensity,OilContent,andIntercon-nectedPorosityofSinteredPowderMetalStructuralPartsandOil-ImpregnatedBearings2E9TestMethodsofCompressionTestingofMetallicMa-terialsatRoomTemperature33.OrderingInformation3.1Ordersformaterialunderthisspecificationshallincludethefollowinginformation:3.1.1Dimensionsand3.1.2Certification(12.1).4.MaterialsandManufacture4.1Bearingsshallbemadebybriquettingandsinteringmetalpowderswithanadditionofgraphitesoastoproducefinishedpartsconformingtotherequirementsofthisspecifi-cation.5.ChemicalComposition5.1ThematerialshallconformtotherequirementsastochemicalcompositionprescribedinTable1.6.PhysicalProperties6.1Density—Thedensityofbearingssuppliedfullyimpreg-natedwithlubricantshallbe6.0to6.4g/cm3.6.2OilContent—Oilcontentofbearingsshallnotbelessthan17%whendeterminedinaccordancewithTestMethodB328.6.3RadialCrushingStrength—Radialcrushingstrengthdeterminedasprescribedin9.2shallbenotlessthannorgreaterthanthecalculatedvaluelimitsusingtheminimumandmaximumKvaluesgivenbelowandusingthefo...